Marking edges (mapping)

Refinish application defects|

Cause Incorrect ratio of hardeners and thinners in materials Layers of materials too thick Material …

Marking edges (mapping)

Pollution in the surface varnish coating

Refinish application defects|

Cause Surface to varnish not cleaned properly Dirty paint spray booth Filters in paint spray …

Pollution in the surface varnish coating

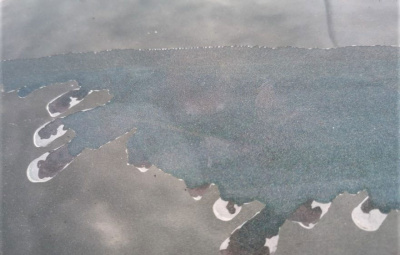

Gasifying

Refinish application defects|

Cause Layers of material too thick Too a short time before drying the material The …

Gasifying

Loss of adhesion

Refinish application defects|

Cause Lack of recommended thickness for the materials (think, thick) Use of wrong hardeners and …

Loss of adhesion

Damp patches

Refinish application defects|

Cause Incorrect viscosity of the material Uneven spread of the varnish Too a short time …

Damp patches

Orange peel, lack of flow

Refinish application defects|

Cause Too a small nozzle on a spray gun Too high viscosity of varnish Too …

Orange peel, lack of flow

Loss of gloss

Refinish application defects|

Cause Lack of recommended thickness for materials (thin, hard) Use of wrong hardeners and thinners …

Loss of gloss

Crackings on the surface after the repair

Refinish application defects|

Cause Incorrect gradation of sand paper Bad preparation of the surface for the applied materials …

Crackings on the surface after the repair

Water stains

Refinish application defects|

Cause Wrong ratio of a hardener A distrupted curing process (material not hardened enough) Too …

Water stains

Blisters

Refinish application defects|

Cause Lack of insulation of polyester materials Water condensation when temperature change Polluted installation of …

Blisters

Discolouration

Refinish application defects|

Cause Bad preparation of the surface to repair Remains of grease from bituminous mass Wrong …

Discolouration

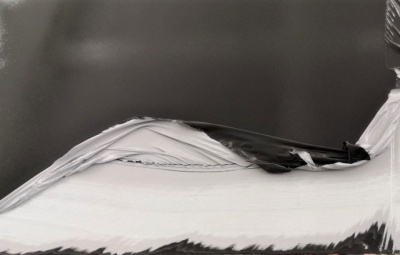

Ruffle, lifting of a coating

Refinish application defects|

Cause Wrong choice of materials (hardeners, thinners) Not properly isolated substrate Thickening of layers of …

Ruffle, lifting of a coating

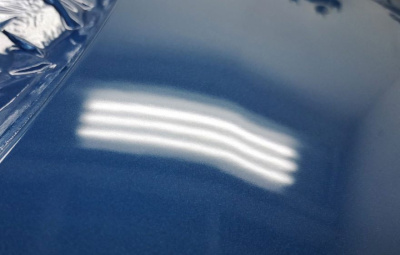

Holograms, effects after polishing

Refinish application defects|

Cause Careening of the polishing machine Wrong polishing compound and applicator Too a short time …

Holograms, effects after polishing

Holes, pinholes

Refinish application defects|

Cause Too thick layers of polyester putty Airlocked polyester putty , Too a short evaporation …

Holes, pinholes

Clouds on metallic

Refinish application defects|

Cause Inappropriate viscosity of material Wrong application technique Too dry spray on material Wrong placing …

Clouds on metallic

No adhesion between a base coat and primer

Refinish application defects|

Cause Lack of recommended thickness of materials (thin, thick) Use fine-grained sand paper during primer …

No adhesion between a base coat and primer

No adhesion between a base coat and a clearcoat

Refinish application defects|

Cause Lack of recommended thickness of materials (thin, thick) Too short evaporation time of base …

No adhesion between a base coat and a clearcoat