Aluminium

Wypełniająca szpachlówka poliestrowa z aluminium

Warianty

| Kolor | Nr art. | Pojemność | Ilość w kartonie |

| ciemnoszary | 1245 | 1,8 kg | 6 |

Stopień połysku

mat

Dokumentacja techniczna

Video

Opis

Wypełniająca szpachlówka poliestrowa z dodatkiem pyłu aluminiowego. Szczególnie polecana do naprawy elementów karoserii narażonych na zmiany temperatur. Charakteryzuje się zwiększoną odpornością na drgania mechaniczne i dobrym odprowadzaniem ciepła.

Zalety

- Bardzo dobra przyczepność do metali.

- Dobre przewodzenie ciepła.

- Bardzo dobra jakość szlifowania.

Podłoża

Produkt wykazuje bardzo dobrą przyczepność do podłoży różnego rodzaju. Może być aplikowany na:

- Stal i Aluminium po zmatowaniu i odtłuszczeniu.

- Ocynkowaną Stal po zmatowaniu i odtłuszczeniu.

- Przeszlifowane laminaty poliestrowo-szklane (GFK/GRP), szpachlówki poliestrowe, podkłady akrylowe i epoksydowe.

- Dobrze przeszlifowane stare lub fabryczne powłoki lakieru.

Uwaga: Nie aplikować szpachlówek poliestrowych bezpośrednio na podkłady reaktywne, 1-komponentowe produkty akrylowe i nitrocelulozowe.

Ważne informacje dotyczące użycia produktu

odtłuścić

Mieszanie wg wagi

100 : 2

Czas życia

4 ÷ 7 min. / 20°C

Czas utwardzania

20 ÷ 30 min. / 20°C

P80 ÷ P120

P120 ÷ P320

Proces aplikacji

-

Zastosowanie

Wypełniająca szpachlówka poliestrowa szczególnie polecana do napraw elementów karoserii narażonych na zmiany temperatur.

-

Proporcje mieszania wg wagi

Szpachlówka: 100

Utwardzacz: 2Wymieszać dokładnie aż do uzyskania pasty jednolitego koloru. Mieszać ostrożnie, aby nie zapowietrzyć szpachlówki.

-

Grubość warstwy

Szpachlówka może być aplikowana w kilku cienkich warstwach. Po każdej z nich produkt powinien być utwardzony. Zeszlifować przed nałożeniem kolejnej warstwy.

Czas życia to 4÷7 minut w 20°C.

-

Czas utwardzania

20÷30 minut w 20°C.

Temperatura poniżej 20°C znacząco wydłuża czas utwardzania produktu.

-

Szlifowanie

Szlifowanie zgrubne (na sucho): P80÷P120.

Szlifowanie wykończeniowe (na sucho): P120÷P320

-

Suszenie promiennikiem IR

5÷7 minut fal krótkich, w zależności od grubości warstwy i rodzaju promiennika.

Nie przekraczać temperatury 60°C.

Stosować według zaleceń producenta sprzętu.

Odczekać około 5 minut przed rozpoczęciem suszenia promiennikiem.

-

Dalsze prace

Na szpachlówki poliestrowe można aplikować:

- 2-komponentowe szpachlówki poliestrowe,

- 2-komponentowe poliestrowe szpachlówki natryskowe.

- 2-komponentowe podkłady akrylowe.

- 2-komponentowe podkłady epoksydowe.

-

Uwagi ogólne

- Nadmierna ilość utwardzacza może spowodować problemy z odbarwieniem lakieru bazowego/nawierzchniowego!

- Podczas pracy z produktami 2-komponentowymi zaleca się używać sprzętu ochrony osobistej. Chronić oczy i drogi oddechowe.

- Pomieszczenia powinny być dobrze wentylowane.

- Narzędzia powinny być myte bezpośrednio po aplikacji.

Uwaga: W celu zachowania bezpieczeństwa należy zawsze postępować zgodnie z instrukcjami zawartymi w karcie MSDS produktu

Zapytaj o produkt

Powiązane produkty

Szpachelki „japonki”

Szpachelki „japonki”Szpachelki „japonki”

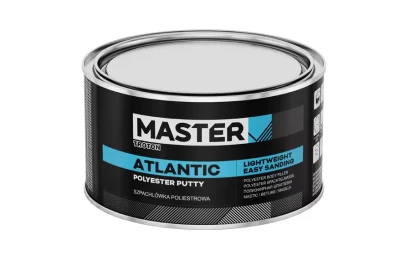

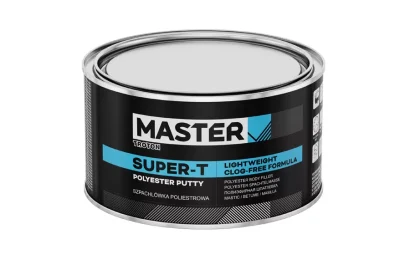

Light

LightLight

Lekka wypełniająca szpachlówka poliestrowa

HS 5:1

HS 5:1HS 5:1

Podkład akrylowy

MS 2:1

MS 2:1MS 2:1

Nawierzchniowy lakier bezbarwny

Przeczytaj więcej o produkcie na blogu

Szpachlówki – trudno bez nich wyobrazić sobie prawidłowe przygotowanie powierzchni

Szpachlówki|

Szpachlówki – trudno bez nich wyobrazić sobie prawidłowe przygotowanie powierzchni