Repair Set Speed

Speed Repair Set

Variants

| Art. no. | Capacity | Quantity per carton |

| 6147 | 250 g resin + hardener + glass fiber mat 0,25m2 | 16 |

Gloss grade

semi-matt

Technical documentation

Description

Fast polyester repair set designed for manual lamination. Polyester resin in combination with the glass fiber mat is perfect for repairing car bodies, caravans, boats and yachts.

Advantages

- Very good adhesion to metal.

- Good hardness with high elasticity.

- Minimal shrinkage.

- Good sanding properties.

Substrates

The product has very good adhesion to various substrates. It can be applied over:

- Steel and aluminum after flatting and degreasing.

- Zinc coated steel after flatting and degreasing.

- Sanded glass fibre (GFK/GRP), polyester putties, acrylic and epoxy primers and existing paint coatings in good condition.

Caution: Do not apply the polyester resins directly on the wash primers, 1K acrylic and nitrocellulose products

Important informations

Mixing ratio

100 : 2

Gelling time

9 ÷ 11 min. / 20°C

Hardening time

25 ÷ 30 min. / 20°C

P80 ÷ P120

Application process

-

Use

Especially recommended for fast repair of large damages and corroded parts of the car body.

-

Mixing ratio by weight

Resin : 100

Activator : 2Stir very well.

-

Gelling time

9-11 minutes at 20°C

Several layers of mat can be applied.

-

Hardening time

25÷30 minutes at 20°C.

Temperatures below 20°C significantly increases the drying time.

-

Sanding

Coarse sanding (dry): P80÷P120.

-

- Prepare suitable piece of glass mat, approximately 2 cm bigger than the damaged place.

- Mix the resin with the hardener and spread it onto the cleaned surface using a brush.

- Place the mat, press it and soak with resin using a brush. Several layers of the mat can be applied.

- Wait approximately 25 minutes. Mechanically sand the dried laminate surface or level it up with a polyester putty.

- Minimum application temperature is +10°C.

Caution: Do not pour the remains of the mixed resin and hardener back to the tin.

-

Further work

Polyester laminates can be directly over coated with:

- 2K polyester body fillers and putties.

- 2K polyester spray fillers.

- 2K epoxy putties.

- 2K acrylic primers.

- 2K epoxy primers.

-

General notes

- The rooms should be well ventilated.

- When working with 2K products, it is recommended to use personal protection equipment. Protect the eyes and air ways.

- Clean the equipment immediately after use.

Caution: To maintain safety, always follow the instructions given in the MSDS for

the products.

Ask about this product

Related products

Flat nylon brush

Flat nylon brushFlat nylon brush

Silicone Remover

Silicone RemoverSilicone Remover

Silicone Remover

Light

LightLight

Lightweight filling polyester body filler

Epoxy Primer 10:1

Epoxy Primer 10:1Epoxy Primer 10:1

Epoxy primer

See also other products

Glass mat

Glass matGlass mat

Polyester Resin

Polyester ResinPolyester Resin

Polyester resin

Repair Set

Repair SetRepair Set

Repair Set

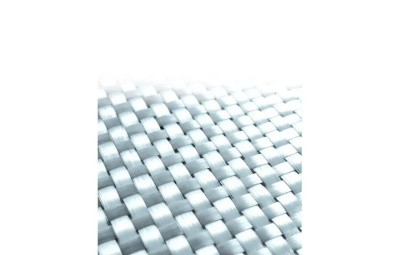

Woven roving fabric IT

Woven roving fabric ITWoven roving fabric IT

Woven roving fabric IT